Speedmart Tech Support

The following text is intended as merely a guideline based on the experiences over the years. We acknowledge there will be other opinions that may be as successful or possibly even more successful than those set forth below. There is no one "right" method. As racers, you may want to use the information as a starting point and modify your technique based on your own experience and success at the track you are racing.

SIPING ONLY: When applying this technique to a dirt sprint tire, siping will do many things. First, this will help the tire build heat quicker which will help the tire "fire" better. Siping will also dissipate heat when the tire gets to operating temperature and the sipes open up. If you are using a fairly hard tire, siping will help create a "graining" effect which will help keep the tire from "sealing" over. The only sprint compound not normally recommended siping is a D10 tire because it is already very soft and may result in "tearing" of the tread blocks and will result in loss of traction. As such, you rarely see Hoosier sprint tires siped for qualifying since the D10 compound is normally the qualifying compound. Also, never sipe a tire more than half the depth of the tread block. Any deeper than half the depth of the tread block may cause the sipes to rip or chunk out. How much you sipe a tire will come from your own experience through trial and error. Also, like all good racers, pay attention to what techniques your competitors are using. They may have learned something you have yet to experience.

GROOVING ONLY: We recommend grooving a tire if the track is very wet and heavy or if the track is a hard surface with a lot of loose dirt blowing across the surface. Grooving will help channel the dirt out the tire to help maintain a good contact patch between the tire and track surface--just like the grooves in your street tire which help keep your car from hydroplaning. Grooving will also create more edges for better traction or grip. Just as with siping, how much you elect to groove your tires depends on what you have experienced in the past along with watching what the top finishing drivers are doing as well.

SIPING AND GROOVING: Combining both siping and grooving is normally done in both heat and feature races. You may need the grooves for cleaning but yet you also need to do some siping to help the tire "fire" and to allow the tread surface to properly "grain".

SIPING

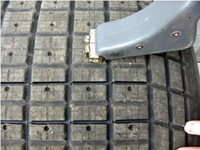

| Generally, the grooving blade is reversed to result in two independent cutting blades. The depth should be set no deeper than 1/2 the depth of the tread blocks. Deeper than 1/2 the depth may cause individual tread blocks to rip or chunk out. When setting the depth of the blades for siping, place the siping head on the tread block and visually adjust the depth to 1/2 the thickness of the block |  |

| Proper siping of this tire has resulted in a very nice texture or grain to the tread surface. The siping allowed the tire to "fire" quickly on starts or re-starts and as the race went on, the sipes allowed heat to be expelled which resulted in less chance of blistering. |  |

| A sipe is simply a razor thin cut or slit in the rubber tread block. |  |

| Straight grooves work best for forward bite. We recommend no wider than 3/16" wide of grooves. Wider than this may tend to cause the tread block to rip or peel back. |  |

| When using a very hard compound, you may want to 1/4 groove the tread blocks allowing for a greater degree of "cleaning" grooves and more edges for increased traction. Usually the tire is cut vertically and then horizontally or vice versa |  |

| Grooves can also be cut at angles. Angled grooves will result in a combination of increased side bite as well as increased forward bite. |  |

| Unlike siping in which you should go no deeper than 1/2 the depth of the tread block, grooving can and generally is the full depth of the tread block. Also, the "hole" in the tread block(s) is called a "heat dispersion vent" which serves to reduce the chances of blistering. |  |

Proper grooving and siping techniques will ultimately result in a better performing sprint tire which will in turn result in higher finishes.

Recommended operating temperatures of Hoosier sprint tires under various track conditions?

Optimum temperature ranges for Hoosier Sprint tires:

The following is a table with temperature limitations for Hoosier Sprint tires. Please keep in mind that there are a number of variables that must be taken into account when taking tire temperatures. Some of these variables are:

1. Needle pyrometer vs. surface pyrometer vs. infrared pyrometer. The temperatures listed are from a needle pyrometer. Surface pyrometer readings will be 10 to 20% lower than needle readings. Infrared pyrometer readings should be close to surface pyrometer readings provided that the distance from the pyrometer to the tire is in the range designed for the pyrometer being used. This distance is typically about 6-8".

2. The time between being at full speed on the track and taking the reading. This variable is very hard to factor out. If tire temps are high and the ambient temperatures are low the tire will cool very fast and your temperature readings will be misleading.

3. Location on the tire. This includes which row of blocks on the tire and where in the block you are checking. It is best to always check the same rows. It is also best to stay at least 3/8" away from a groove or heat dissipation vent. Temperatures on the first inside row and the outer 2 rows of a 105/18 should be excluded. On left rears, the 1st inside and 1st outside rows should be excluded.

4. The amount of wear the tire sees: As tread rubber wears down there is less mass to heat up so tire temps will be lower.

5. Pyrometer calibration.

These are temperature readings taken within 3 to 4 minutes after the car is at full speed on full tread depth non-grooved tires. If tire temps are below the minimum listed the tire will be slow to fire. If tire temps are above the maximum listed the tire will slow down due to fatigue or blistering. The average temperature of the tire should be within the ranges listed below. If one row on the tire is running hotter than the listed ranges try grooving that row in a circumferential direction.

D10 ambient temp up to 200°F

RD12 ambient temp up to 220°F

D12 160°F up to 250°F

RD15 160°F up to 230°F

D15 160°F up to 260°F

D20 180°F up to 260°F (unless it is a high wear situation)

F55 200°F up to 280°F

A good balance between left rear and right rear tires is also important. A good rule of thumb is that the left rear should be around 20-30°F cooler than the right rear. One exception is a high speed, high banked track like Eldora. At Eldora we typically see LR temps about equal to RR temps.

A common pitfall is that if the tires are running too hot it is not always the best thing to run a harder tire. A harder tire provides less traction (except F55) and will spin more which in turn will make it run hotter. Sometimes a softer tire will hook the car up better or grain a little. Both of these conditions will make the tire run cooler.

With "RD" type tires being high traction tires for dry slick tracks and "D" type tires being for high heat, high speed tracks these are a few of the most common combinations:

"D" LR and "D" RR (Eldora-type tracks)

"RD" LR and "D" RR (Lincoln Speedway or Williams Grove Speedway when the track is fast)

"RD" LR and "RD" RR (Lincoln Speedway or Williams Grove Speedway when the track is slow)